Psv For Hydrotest - Pressure Tests Of Piping Systems Hydrotest Vs Pneumatic Test What Is Piping / Hydrostatic testing is the most common method employed for testing pipes and pressure vessels.

Psv For Hydrotest - Pressure Tests Of Piping Systems Hydrotest Vs Pneumatic Test What Is Piping / Hydrostatic testing is the most common method employed for testing pipes and pressure vessels.. Hydro test test area shall be barricaded and provide warning boards to prevent personnel entry. In a digital hydrostatic test, the operator utilizes a digital pressure gauge outfitted with the capabilities to read. Standard materials include 316 stainless steel bodies and seat glands. After the satisfactory completion of the tests, air vents need to be opened during draining to admit air and prevent collapsing of the test system and shall be depressurized at a rate should not exceed 1 bar (15 psi) per minute until the pressure has been reduced to 40 % of the test pressure. Using this test helps maintain safety standards and durability of a vessel over time.

Pressure safety valve testing just got a lot easier. Is normally achieved by connecting a pressure relief valve onto the assembly under test. Using this test helps maintain safety standards and durability of a vessel over time. This video explains how to calculate the hydrotest pressure of vessels and piping systems as per asme & ped. A hydrostatic test is a way in which all pressur.

If this is the case, then the 10/13 rule for tube rupture case is not applicable and instead a.

Explosions have caused far too much damage in companies over the years, and though pressurized tanks and vessels are equipped with … best practices for testing pressure relief valves: In over 40 years of observing/witnessing hydro testing of piping both in service and newly fabricated i've never seen a pipe burst from the calculated test pressure. The relief valve(s) shall be tested, dated, and tagged within two weeks prior to the pressure test for new construction projects, and within three months for maintenance operations. As a dedicated component of the tank it is required to meet the design criteria of the tank's mawp. The hp water pump discharge pipe is designed for 140 barg and normal operating pressure at 124 barg. The code recommends that the metal temperature during hydrostatic test be maintained at least 30°f (17°c) above the minimum design metal temperature, but need not exceed 120°f (48°c), to minimize. Piping hydrotesting is done at 1.5 x design pressure unlike equipment which is 1.3 x design pressure. Whereas the hydrotest pressure is meant to check the integrity of pipeline/vessel after fabrication/carrying modification & repair without using the process fluid. Ensures that the test area is properly flagged, barricaded, or otherwise controlled to prevent unauthorized personnel entry. Pressure relief valve are critical to obtaining maximum protection. Safety precautions of hydro test: And welding documentation completed and acceptable. The pressure test relief valve shall be accompanied with a calibration certificate that includes the cold differential test pressure (cdtp), test date and the.

Types, design, and construction a pressure relief valve must be capable of operating at all times, especially during a period of power failure; Pressure safety valve testing just got a lot easier. The corrosion occurred due to water ingress between the concrete and the steel legs. The valve is designed to limit system pressure, and it is critical that they remain in working order to prevent an explosion. Before the new piping system runs into operation, it is necessary to make sure that, they are correctly commissioned, and are ready to use.

This video explains how to calculate the hydrotest pressure of vessels and piping systems as per asme & ped.

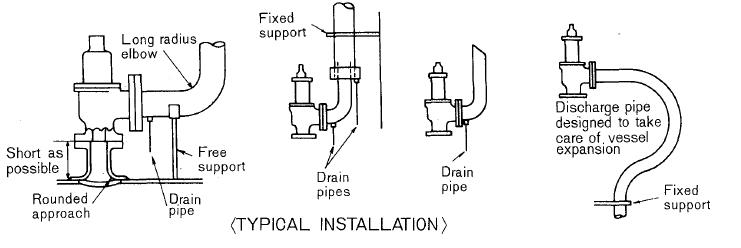

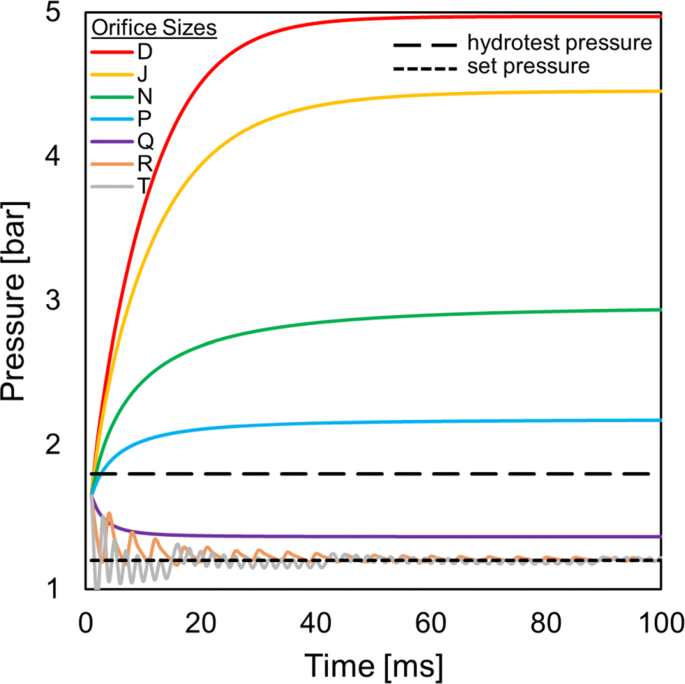

Every steam, hot water boiler should have at least one psv valve. The relief valve(s) shall be tested, dated, and tagged within two weeks prior to the pressure test for new construction projects, and within three months for maintenance operations. Dear all, why asme b31.3 specify the hydrotest pressure for process lines are 1.5 times of design pressure. However, they require less test equipment to achieve the same result. Regardless, the discharge piping for each pressure relief valve should not be smaller than the nominal pipe size of the pressure relief. The pressure test relief valve shall be accompanied with a calibration certificate that includes the cold differential test pressure (cdtp), test date and the. Before the new piping system runs into operation, it is necessary to make sure that, they are correctly commissioned, and are ready to use. Pressure relief valve discharge piping should be sized so that any back pressure that may exist or develop will not reduce the capacity of the pressure relief valve below that required to protect the equipment. Why not other fractions i.e., 1.6 or 1.4 times of design pressure. The length of each test section to be decided according to site requirements, but limited to a maximum of 1 km. Hydro test test area shall be barricaded and provide warning boards to prevent personnel entry. Ensures that the test area is properly flagged, barricaded, or otherwise controlled to prevent unauthorized personnel entry. Relief valves are offered in pressure ranges:

The hp water pump discharge pipe is designed for 140 barg and normal operating pressure at 124 barg. Regardless, the discharge piping for each pressure relief valve should not be smaller than the nominal pipe size of the pressure relief. The relief valve(s) shall be tested, dated, and tagged within two weeks prior to the pressure test for new construction projects, and within three months for maintenance operations. 31 to prevent/reduce operator presence in the danger zone, determine and identify optimum positions for control valves and monitoring devices such as pressure gauges and flow meters, locating them away from the test area. Safety is of the utmost importance when dealing with pressure relief valves.

The pressure test relief valve shall be accompanied with a calibration certificate that includes the cold differential test pressure (cdtp), test date and the.

As pressure control valve, hydraulic pressurepressure relief valves maintain the pressure in whole hydraulic system or partial system within a specific level or range, for example: When conducting tests at freezing temperatures. Piping hydrotesting is done at 1.5 x design pressure unlike equipment which is 1.3 x design pressure. Explosions have caused far too much damage in companies over the years, and though pressurized tanks and vessels are equipped with … best practices for testing pressure relief valves: Types, design, and construction a pressure relief valve must be capable of operating at all times, especially during a period of power failure; Is normally achieved by connecting a pressure relief valve onto the assembly under test. However, they require less test equipment to achieve the same result. The length of each test section to be decided according to site requirements, but limited to a maximum of 1 km. Pressure relief valve discharge piping should be sized so that any back pressure that may exist or develop will not reduce the capacity of the pressure relief valve below that required to protect the equipment. Hydro test or hydrostatic test is a type of pressure test performed on piping and pressure vessels to check system integrity under pressure condition. The corrosion occurred due to water ingress between the concrete and the steel legs. Pressure relief valve are critical to obtaining maximum protection. This video explains how to calculate the hydrotest pressure of vessels and piping systems as per asme & ped.

Komentar

Posting Komentar